Recyclable PP Retort pouch

One of the major problems that many manufacturers in the food packaging industry would encounter during their efforts in developing recyclable pouches is that the PE printing performance is not as good as traditional PET film.

Yet Queenly have overcome all of these printing difficulties through selecting the right type of Mono PP material, adjust the ink and printing machines so that the printing effect of our Mono PP pouches could be as excellent as that of our other normal printing materials.

Our PP Recyclable retort pouchs could be a new features for your products since the touch feeling of Mono PP is so much different from that of PET.

Sustainability never looked so good!

The concept of mono-material packaging has gained popularity in recent years due to its positive environmental impact and increased recyclability. By using a single type of material, the packaging becomes easier to recycle and reduces the need for complex sorting processes, making it more environmentally friendly.

Spouted pouches are a type of flexible packaging that incorporates a spout or nozzle for dispensing liquids or semi-liquids. These pouches are commonly made from various materials, including Polyethylene (PE).

Here are some key features and advantages of spouted pouches made from PE:

Pack for your product:

- Coffee & Tea

- Pet Food

- Processed Food

- Beverages

- Frozen Food

- Condiments & Sauces

- Pharmaceutical & Medical

- Dry Food Stuffs & Confectionery

- Home & Garden

- Health & Beauty

Features:

1.Good moisture and oxygen resistance performance;

2.High temperature;

3.Good sealing, high quality printing ;

4.Food grade material, non-toxic, no smell, tasteless, moisture, oxygen barrier, barrier performance is excellent.

5.Easy to carry ;

6.Cost saving ,fadhionable and beautiful

5 Steps to Make Successful Product Packaging

We help our customers determine the perfect packaging for their products. This process consists of five steps:

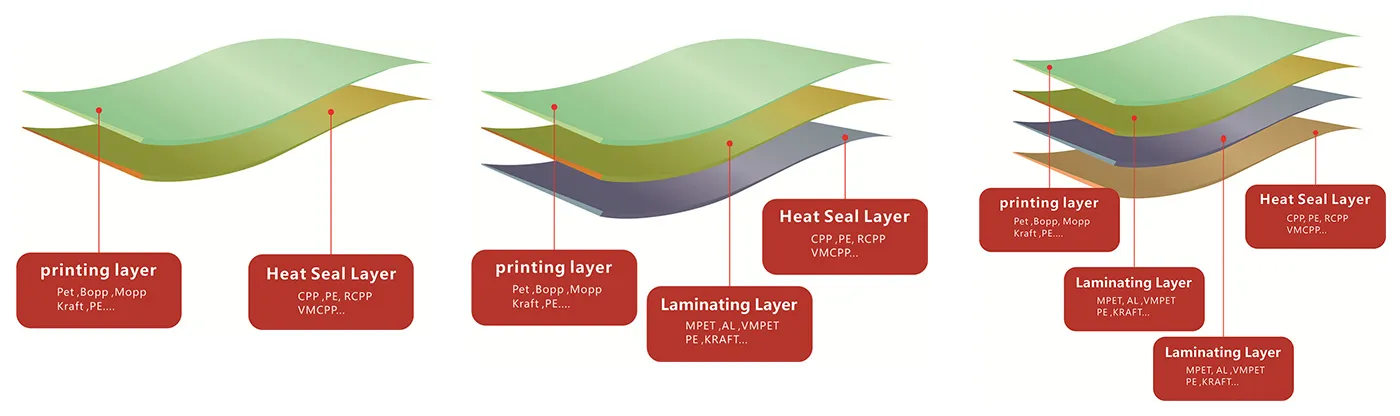

1 Material Structure

– Type of Product:What is it used for ? Is it a powder, liquid, sharp, heavy, greasy, oily, Acid or Alkaline ,hot & cold (temperature) etc.?

– Visibility: See your product comepletely or partrial or Completely Opaque ?

– Feature: Glossy or Matt or othe special .

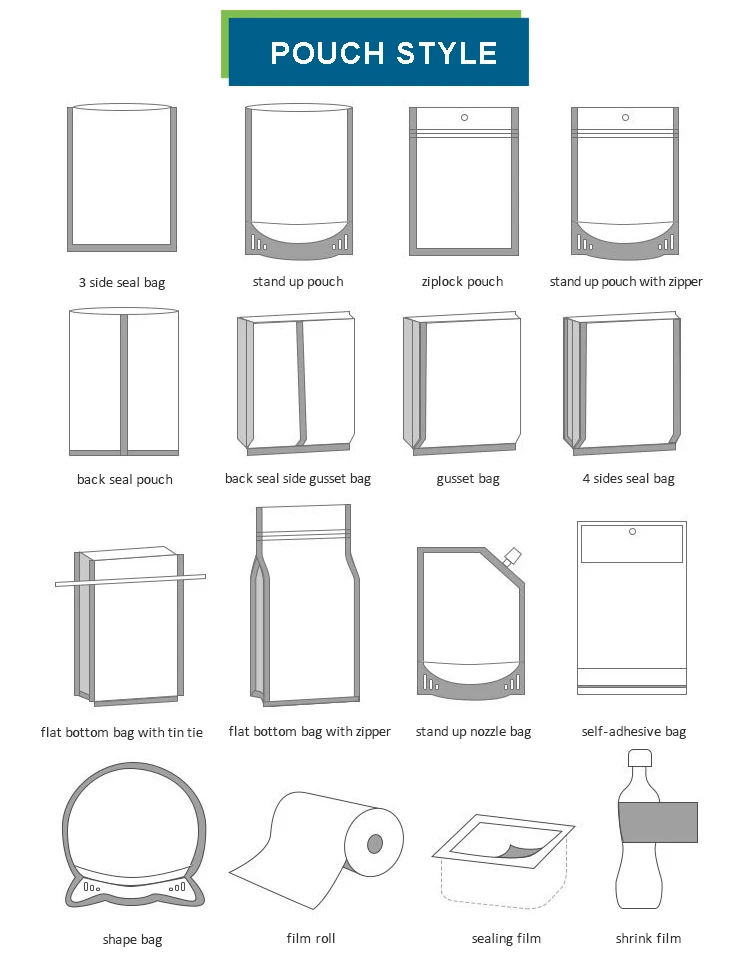

– Style: The Handle & Valve style you prefer to.

– Conditions:

① What kind of conditions will your packaged product be subjected to throughout your supply chain?

② Does your pouch need to withstand heat, high risk of puncture, rough handling, or other potentially damaging environments?

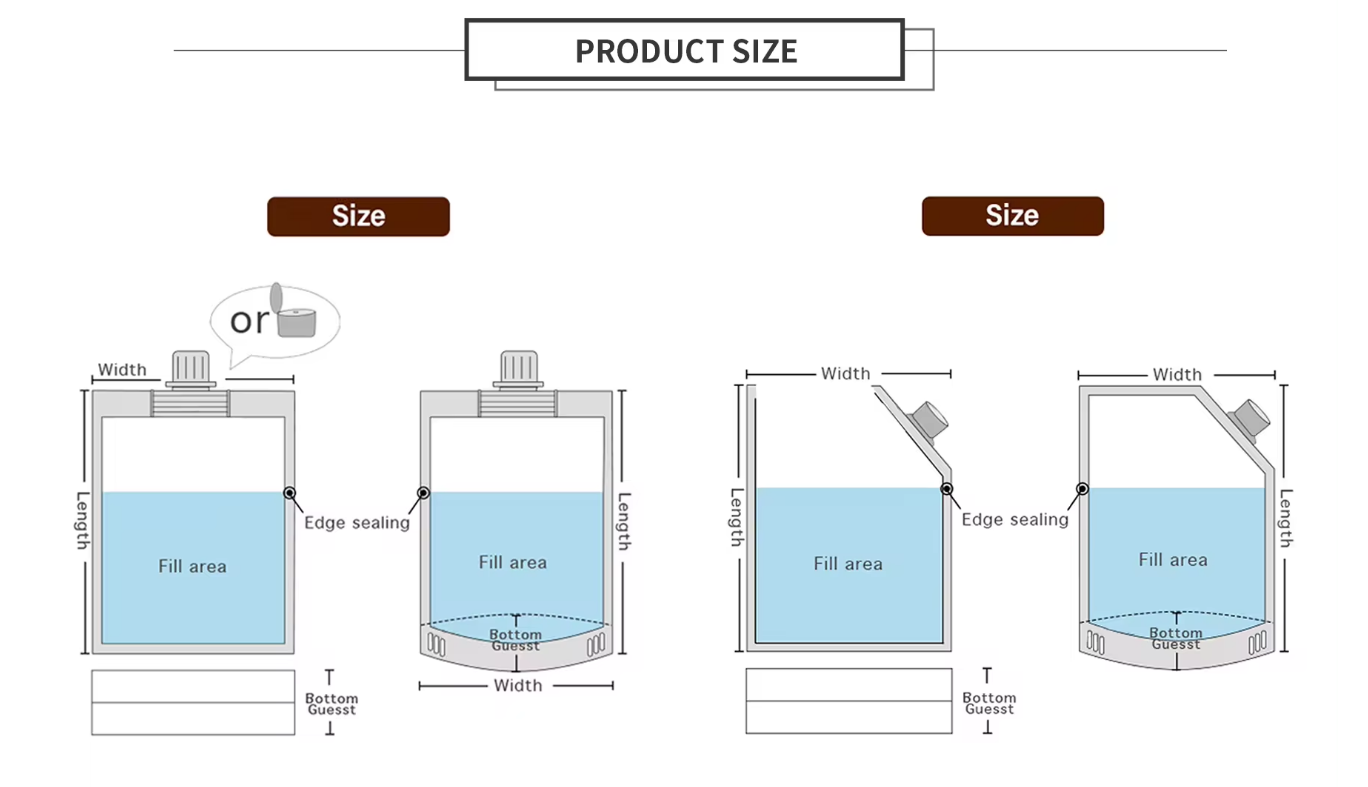

2 Size

– Not sure what size you need? We will hand craft a sample for you in your requested size to test for fit.

– You just need to tell us your bag’s bear capacity or weight

3Artwork

– 3 digital versions in Adobe Illustrator or Photoshop file format:

– AI, PSD, CORELDRAW, PDF

- 1 EPS copy converted into outline

- 1 EPS copy unconverted

- 1 PDF

– A copy of your true color standards (PMS numbers or color samples) so your colors can be matched identically.

– Outlines around all of the text in your printed stand up pouch design. Outlines turn text into small graphic designs, so your fonts won’t be distorted in the translation process.

– All of the individual images used in your design with a resolution of at least 350 dpi. Make sure not to flatten your image layer

-The UPC.

4Manufacturing

– It Takes around 15-21 days finished products , if you are urgent for any project , we could discuss for the manufacturing plans .

– After our cylinders making will make a basic film proof

5Shipping and Payment

– We help aboout DDP shipping by sea to your door or you have agent we ship to your agent . After goods finished could determine the best shipping way for you .

– All of the cylinders and 40% desposit ,balance before shippment .

Reviews

There are no reviews yet.