Factory

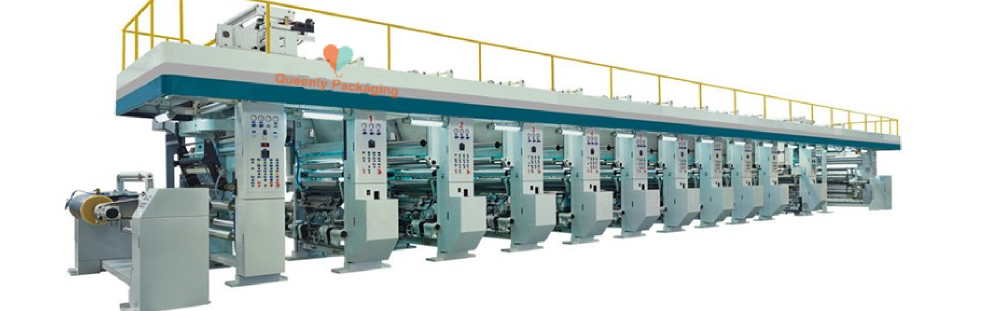

Industry-leading Production Equipment:

In order to improve the production efficiency and product quality,Queenly Packaging increase investment in equipment,

introduce advanced equipment from Italy, Germany, Japan, etc., and establish a new plant meeting GMP requirement,

supporting 6 sets of 12-color printing and composing lines.

With advanced equipment and exquisite technique, Queenly converge excellent product quality with high production capacity

to achieve 25,000 tons annual production, leading in plastic packaging industry.

Quality Assurance:

As a leading manufacturer of plastic flexible packaging,

Queenly Packaging have established a ” more professional, more stable and more perfect” image in the industry.

Queenly Packaging complies with ISO9001 and BRC food safety management system strictly,

all the product materials have had an inspection of physical routine, hygienic properties,

microbiological and characteristics test by using advanced testing equipment,

scientific management and control system so that to ensure product quality , safety and reliability.

Safe and satisfactory packing for Well-Packed Goods:

Proper packing plays an important role in safe transportation of goods.

Our goods are safely packed in cartons and then fixed onto pallets with double straps.

Each corner of cartons are protected by angle boards,

and a layer of transparent plastic film is cover on cartons to further fasten the goods and to protect them from getting wet.

Stable product quality and timely delivery:

1. Strong production capacity :

We have a full range of production equipment and our annual production capacity reaches 25,000 tons.

2. Stable product quality :

All of our products go through strict quality inspection before they are sent to our customers.

3. Timely delivery :

Our production lead time is 30 days upon confirmation of orders and receipt of all the necessary production details.